1

The First Oilers

In the winter of 1916-17, it became apparent to most officers in the U.S. Navy that it was only a matter of time before the United States would become involved in the conflict then raging in Europe. Anticipating the need to deliver fuel under way, the officers of the Maumee began to formulate a procedure for refueling destroyers at sea. Commissioned in October 1916 as a naval auxiliary, Maumee was the second vessel of her class to enter service in the U.S. Navy. The first, the Kanawha, had only been commissioned a year earlier. Laid down by the Mare Island Navy Yard, both vessels were the first tankers in the world to be designed and built specifically for naval service. Originally classified as fuel ships, they were authorized by act of Congress on 22 August 1912 and were built as oilers in response to the changing composition of the U.S. battle fleet. The U.S. Navy was then in the process of switching from coal to oil as the preferred fuel for its capital ships and would soon need tankers to service the Nevada and Oklahoma--the first battleships designed to burn fuel

oil exclusively.1

The term "oiler" had yet to be coined when Kanawha and her sister ship Maumee were laid down, thus they were called "fuel ships" or, as was the case in certain publications, "oil carriers." At the time of their construction, they were similar in design to contemporary tankers of their day, although the four sets of centerline booms standing upright along the cargo deck were prominent features not found on their merchant cousins. These were designed so that multiple fuel hoses could be suspended on both sides of the ship as needed to speed the transfer of fuel oil to warships moored alongside. The number and location of these booms appear to have been vestiges of the multiple

NOTE: In U.S. Navy parlance, all tankers (AOs) are officially termed "oilers," though unofficially the term is often used to describe only those AOs fitted to refuel at sea; others not so equipped and used to carry bulk oil from port to port are popularly referred to as tankers. This convention will be followed throughout this text.

--5--

derrick arrangement that the navy had previously installed on its colliers in an effort to reduce the time needed for coaling. This arrangement, which is clearly shown on early photographs of both vessels, did not prove satisfactory as can be seen in the later photos, which show a relocated pilot house moved from its extreme forward position to a location closer to midship.2

Taking her name from the river in West Virginia, Kanawha, the first to be completed, was launched on 7 November 1914 at the Mare Island Navy Yard on San Francisco Bay.3 Although conventionally powered by two triple-expansion reciprocating steam engines, her machinery spaces housed a propulsion plant nearly twice as powerful as those normally installed on a commercial vessel of the same size. Rated together at 5,200 s.h.p. (shaft horsepower) maximum output, her twin engines (each connected to a separate shaft driving one of her two screws) were sized to provide enough power for the 14-knot cruising speed deemed necessary for Kanawha if she were to keep up with the fleet. Each engine weighed 103 tons and had to be partly disassembled before it could be installed on the ship. Built by the Mare Island yard and assembled on the erecting floor of its machine shop, the engines were lifted onto railroad flatcars, hauled to the waterfront, and individually hoisted aboard the completed hull. It was claimed that his procedure saved eight to ten thousand dollars in the cost of construction-- a rather substantial sum in those days.4

Completed in the spring of 1915, Kanawha was commissioned on 15 June as a naval auxiliary and placed into service with a merchant crew of twelve officers and sixty-six men under the command of Master W. E. Kennedy of the Naval Auxiliary Service.5

Well before construction was started on either ship, the decision was made to equip the Maumee with diesel engines, then a relatively new technology that appeared to offer better fuel economy than could be obtained from the best steam plant then available.6 This was the golden age for marine engineering--a time when the U.S. Navy was experimenting with a variety of new developments in engine technologies in an effort to find out which would provide the best performance. Placing diesels aboard the Maumee would afford an excellent opportunity of comparing the performance of this type engine with the conventional machinery then in common use, since the two ships would be identical in all other respects, would burn the same grade fuel, and were expected to be employed in the same type of duty.

The precedence for installing new types of machinery on fuel ships had been set several years earlier when contracts were first issued for the construction of the Neptune, sister ship to the collier Cyclops authorized in the 1908 program. After the Maryland Steel Company was awarded a construction contract for the Neptune, the company

--6--

Kanawha, taken soon after commissioning in June

1915. Note the four pairs of fueling booms on the centerline of her

weather deck. These appear to be vestiges of the gear developed for

transferring coal from navy colliers and were soon replaced by

outboard davits and/or kingposts. (Author's collection)

submitted a proposal to the Navy Department suggesting that the main propelling machinery be changed to steam turbines with reduction gearing--a rapidly developing engine technology that appeared to offer many advantages. The Bureau of Steam Engineering approved this proposition, but stipulated that the contract be so drawn that in case of failure the turbines and reduction gearing could be replaced with reciprocating engines like those provided for Cyclops. In the year following the start of the work on Neptune, the General Electric Company undertook the installation of turboelectric machinery on another of Cyclops's sisters, the Jupiter. Built by the Mare Island Navy Yard, she was destined to be converted into the navy's first aircraft carrier, renamed the Langley. Electric propulsion proved so successful that it was later adopted by the navy for battleship use.7

Fuel ships were the ideal test bed for evaluating new types of propulsion systems. They were relatively large vessels and were the workhorses of the fleet because of their fuel-ferrying duties; thus the experimental engines installed on these ships would quickly be subject to many hours of operation as they steamed from port to port with the precious fuel needed by the navy's dreadnoughts. As auxiliaries, fuel ships were considered less important to the U.S. Navy than combatants, so the department could afford to risk the potential of degraded performance or loss of reliability in return for the practical experience

--7--

The collier Neptune was the

first large ship in the U.S. Navy powered by a geared turbine. The

multiple booms and kingposts were part of the Marine Transfer System

installed to speed coaling. (U.S. Naval

Institute)

The collier Neptune was the

first large ship in the U.S. Navy powered by a geared turbine. The

multiple booms and kingposts were part of the Marine Transfer System

installed to speed coaling. (U.S. Naval

Institute)

that could be gained from installation of new types of propulsion machinery.

As for the Maumee, the money originally allocated for her

construction was insufficient to cover the cost of the very large diesels that

the department wished to evaluate.8 To cover the added expense of introducing

this new form of motive power into the service, Congress was induced to

appropriate an additional $250,000 for the development of a "heavy-oil engine"

suitable for use on the Maumee.9 Since the Bureau of Steam Engineering had little experience with this technology, it decided to send a naval officer to Germany where most of the large diesels were then being built. The bureau intended to build the engines in one of the navy's yards and wanted to obtain the manufacturing rights along with a set of working plans from a company already engaged in the manufacture of these engines. The person selected, Lt. Chester W. Nimitz, was a promising young officer then in command of the Atlantic Submarine Flotilla. Nimitz, no doubt, was selected to build the engines for the Maumee because he was already familiar with diesels, having commanded one of the few American-built submarines equipped with this form of propulsion.10

After spending several months in Germany in the spring and summer of 1913, Nimitz returned to the United States with plans for a two-cycle, single-acting diesel manufactured by the Machinenfabrik-Augsburg-Nurnberg (M.A.N.) company of Nuremberg, Germany. After

--8--

obtaining bids from various shipbuilding and manufacturing companies, the Navy Department contracted with the Electric Boat Company, the American licensees of the M.A.N. Company, to supply a set of drawings that could be used to build the engines in the United States. Electric Boat obtained the original plans from Germany, translated all measurements from metric to English units, and then supplied the navy with a set of retraced plans that were sent to the New York Navy Yard for comparison with the original German drawings. After approval by the Bureau of Steam Engineering, these were then used by the navy yard to fabricate the engines that were built by the yard's Machinery Division. Except for a few heavy forgings and castings, all parts needed to build the engines were made by the navy.11

Before the completed engines could be installed on board Maumee, the hull, which had been fabricated in the Mare Island Navy Yard, had to be towed from San Francisco to New York.12 One can only speculate as to how this astonishing arrangement came to pass, as it was an extraordinary inconvenience that could only have added to the final cost of the finished vessel. Obviously, the time, energy, and money spent on towing the partially completed ship could have been avoided had Maumee been constructed in New York or, at the very least, in another East Coast yard. Clearly the technical demands involved in constructing diesels dictated the selection of the New York Navy Yard, the most sophisticated of any of the navy's shipyards, but why construct the rest of the ship in California? Political constraints had combined with Congress's desire to distribute lucrative contracts on a geographical basis to cause this remarkable episode of largesse. When Congress first authorized the construction of the two fuel ships in 1912, it stipulated that they "be built in Navy yards, [with at least] one to be built in a Navy yard on the Pacific coast. 13 Though the navy was not required to construct the Maumee on the West Coast, it seems likely that she was laid down at Mare Island in order to comply with the Naval Appropriation Act of 1914. Passed in the month preceding the laying of Maumee's keel, this measure required the navy to make sure that its yards were used to full capacity before it could let contracts to private shipbuilders.14

The Maumee was commissioned on 23 October 1916 under the command of Lt. Cdr. Henry C. Dinger, with a naval crew of forty-five. By then, Dinger was the U.S. Navy's foremost authority on liquid fuels and had authored a number of technical papers on the subject. Nimitz, now even more knowledgeable about diesels, was assigned as the ship's executive officer and chief engineer.15 This arrangement--a billet combining traditional "line" duties with engineering duty--was

--9--

Maumee, shortly aftercommissioning. Note the similarities in appearance to Kanawha. (U.S. Naval Institute)

Maumee, shortly aftercommissioning. Note the similarities in appearance to Kanawha. (U.S. Naval Institute)

not unusual for a naval vessel such as the Maumee, which had a relatively small crew.

After an extended shakedown cruise (cracking of some cylinder jackets forced her return to New York Navy Yard), Maumee participated in fleet training exercises then being conducted in the Caribbean where she was actively engaged in the business of delivering oil and water to all types of vessels, both large and small.16 Under the doctrine then in effect, fueling between ships at sea was conducted only in protected waters while both vessels were moored together. As the crew gained proficiency in the use of the Maumee's specialized fueling gear, the officers on board began to discuss the possibility of refueling ships at sea while under way and made tentative plans to test this concept. However, the ship was much too busy supporting the fleet to conduct experiments at sea.

Once the ship returned to port, however, the officers on board began serious efforts to devise an acceptable means of refueling destroyers while under way. Although preliminary experiments in this important innovation had previously been conducted between the Arethusa and the destroyer Warrington, it had never been attempted in anything but a calm sea.17 The men of the Maumee began this undertaking by obtaining blueprints of the various classes of destroyers showing the location of fuel filling valves, chocks, bitts, and strong points for towing. After careful study, they made sketches indicating the fueling gear and towing rigs that would be needed for each class. It seemed

--10--

Purchased during the Spanish-American War, Arethusa was the U.S. Navy's first tanker. She is shown here in 1911 off the New York Navy Yard. (Naval

Historical Center)

only a matter of time before the United States would be drawn into the conflict then raging in Europe and the problem of getting destroyers across the Atlantic may have been foremost in the minds of the Maumee's officers as they worked out the details of the means proposed for refueling these short-legged warships.

When war was declared on 6 April 1917, the secretary of the navy immediately ordered a division of U.S. destroyers under the command of Cdr. Joseph K. Taussig across the Atlantic to assist the hard-pressed British fleet in combating the German submarine campaign, which was close to strangling the British Isles. Shortly thereafter, the Maumee was sent to a position in mid-Atlantic to serve as a mobile fueling station for the destroyers that followed, which did not (unlike Taussig's ships) have sufficient range to cross the Atlantic without refueling en route.18

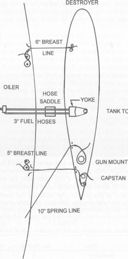

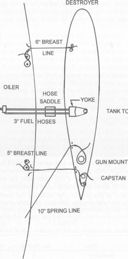

Before the Maumee put to sea, Nimitz was assigned the responsibility for preparing the equipment that would be needed during the forthcoming operation. He was assisted by Lt. (jg) G. B. Davis, Chief Boatswain M. Higgins, and Lt. F. M. Perkins, the Destroyer Force engineer who had come aboard to assist in the planned operation. Together they devised a means for refueling destroyers while under way that required the Maumee to tow the destroyer alongside so that fuel lines could be secured between the vessels--a procedure known as the riding-abeam (later called "broadside") method of fueling. The fueling gear they devised consisted of a 10-inch towing hawser, two 6-inch breast lines, and a number of 50-foot lengths of 3-inch-diameter rubber fuel hose. The team decided to pump fuel through two hoses at the same time to increase the rate of fuel flow thereby reducing the time needed to refill each destroyer's tanks. The hoses would be

--11--

attached to the regular fueling connections on the Maumee, the other end passed to the other ship and inserted into the open manhole of the fuel bunker on the destroyer to be filled. To keep them clear of the sea, the hoses would be supported by a wooden hose carrier, or saddle, suspended from the oiler's cargo booms. These would be rigged in or out and up or down as necessary to facilitate the fuel transfer.19

The first ships met by the Maumee were those of the Fifth Destroyer Division.20 All were 750-tonners having a limited fuel capacity.21 Using the procedures and equipment devised by Nimitz's team, the Maumee successfully refueled the entire division (the Patterson, Jenkins, Drayton, Paulding, Trippe, and Warrington) in a single day. This marked the first time that fueling at sea had been used during a wartime operation. It was also the first time that the transfer of fuel oil between ships under way had been attempted in anything but a flat calm. Sea conditions during the operation were moderate with a long cross swell that caused the Maumee to roll from ten to twenty degrees, with considerable pitching. Although conditions were far from ideal, the Maumee was able to transfer almost twenty thousand gallons of fuel (at the rate of thirty-two thousand gallons per hour) to each destroyer. Despite the fact that all the crews were "green," the times from approach to disconnect averaged just seventy-five minutes for each destroyer, even though a hose was carried away while the last ship was being fueled. The entire operation was completed in ten hours and thirty-five minutes--an extraordinary feat considering the inexperience of the crews and the poor sea conditions.22

Nimitz, who was officially mentioned for his role in preparing and operating the gear employed by Maumee, credits Dinger, whom he characterized as a "superb seaman with a strong engineering background," for the concept, design, and execution of the fueling-at-sea technique used by the crew.23 Dinger later suggested that it would even be practical to eliminate the towing lines, letting the fuel ship maintain a steady course while the destroyer adjusted her speed and helm to stay abreast of the fuel ship. His observation that "this would require very expert judgment and most constant watchfulness" would prove to be most fitting.24 Remarkably, the procedure developed on board the Maumee, less the towing lines predicted by Dinger, was essentially that which would be used by the U.S. Navy in World War II--although it would be many years before the methods developed by Maumee were accepted as standard doctrine.

By 5 July 1917, the Maumee had refueled thirty-four destroyers bound for Europe, and in so doing had established a pattern of mobile logistic support that would later enable the U.S. Navy to keep the fleet at sea for extended periods of time. Though she would make two

--12--

Fig. 1. The riding-abeam (broadside) method devised by the crew of the Maumee for fueling

destroyers while under way (after an original in the Naval Historical

Center)

additional trips to Europe to refuel U.S. naval units, her days of glory were over and she was decommissioned in June 1922--most probably because her engines proved extremely difficult to maintain.

In the meantime, Nimitz, who was promoted to lieutenant commander while aboard the Maumee, was soon transferred back to submarine duty becoming chief of staff to the commander Submarine Force Atlantic Fleet, a position he held throughout the remainder of

--13--

the war. Twenty years would pass before he would again become involved in the development of fueling at sea in an unexpected though important role, the description of which will be saved for later chapters.

As for the other oilers of the Kanawha class, Cuyama, the third to be laid down, was authorized in 1915. Three others, Brazos, Neches, and Pecos, were included in the massive list of ships authorized in the Naval Appropriation Act of 1916; the first to provide a continuous program of naval construction. Prior to passage of this bill, authorization and allotments for new construction had been issued on a year-by-year basis as needed to fulfill the navy's budgetary requirements for the forthcoming fiscal year.25 Signed into law for a three-year building period, though it only provided funding, it empowered the President to add 156 ships (see table 1) to the size of the first year's program.26

The United States was drawn into the "Great War" before the building program could get fully under way. For years the navy had focused its war-planning efforts solely around the battleship with the German high fleet as the most likely adversary. It was not the German battleship, but the German submarine that was the greatest threat to victory. Once engaged in the conflict, the U.S. naval command had to revise its strategy in light of the pressing problems of undersea warfare. After requesting the immediate use of U.S. destroyers, the British made frantic appeals to divert all available naval shipbuilding facilities to the construction of this critical type upsetting the plans originally envisioned for the 1916 program. Although the three oilers authorized

TABLE 1

Ships Authorized, Naval Expansion Act of 1916

No. ships

authorized |

Type |

No. funded |

Amount

appropriated |

| 10 |

Battleship |

4 |

$46,000,000 |

| 6 |

Battle cruiser |

4 |

$6,000,000 |

| 10 |

Scout cruiser |

4 |

$20,000,000 |

| 50 |

Destroyer |

20 |

$4,000,000 |

| 9 |

Fleet submarine |

none |

|

| 58 |

Coast submarine |

30 |

$8,467,000 |

| 1 |

Submarine (Neff) |

1 |

$250,000 |

| 3 |

Fuel ship |

1 |

$1,500,000 |

| 1 |

Repair ship |

none |

|

| 1 |

Transport |

none |

|

| 1 |

Hospital ship |

1 |

$2,350,000 |

| 2 |

Destroyer tender |

none |

|

| 2 |

Ammunition ship |

1 |

$2,350,000 |

| 2 |

Gunboat |

1 |

$ 860,000 |

SOURCE: Navy Yearbook 1916, 480-82.

--14--

Cuyama,after commissioning. Note the bridge

house and the absence of two of the four centerline masts installed on Kanawha. (Naval Historical Center)

in the Naval Appropriation Act of 1916 were retained, their construction was delayed until the end of hostilities and they were not completed for a number of years. The last to be built, Pecos, was finally delivered on 23 April 1921--more than two years after the armistice and five years after she was first authorized. Commissioned on 25 August 1921, she was assigned hull number AO-6[27] and immediately entered service with the fleet where she was to serve for the next twenty years.

--15--

Contents

Next Chapter (2)

The collier Neptune was the

first large ship in the U.S. Navy powered by a geared turbine. The

multiple booms and kingposts were part of the Marine Transfer System

installed to speed coaling. (U.S. Naval

Institute)

The collier Neptune was the

first large ship in the U.S. Navy powered by a geared turbine. The

multiple booms and kingposts were part of the Marine Transfer System

installed to speed coaling. (U.S. Naval

Institute)

Maumee, shortly aftercommissioning. Note the similarities in appearance to Kanawha. (U.S. Naval Institute)

Maumee, shortly aftercommissioning. Note the similarities in appearance to Kanawha. (U.S. Naval Institute)